|

|

|

|

|

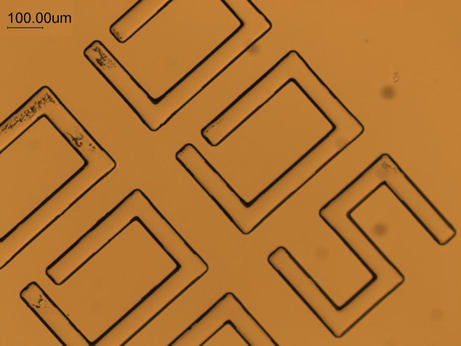

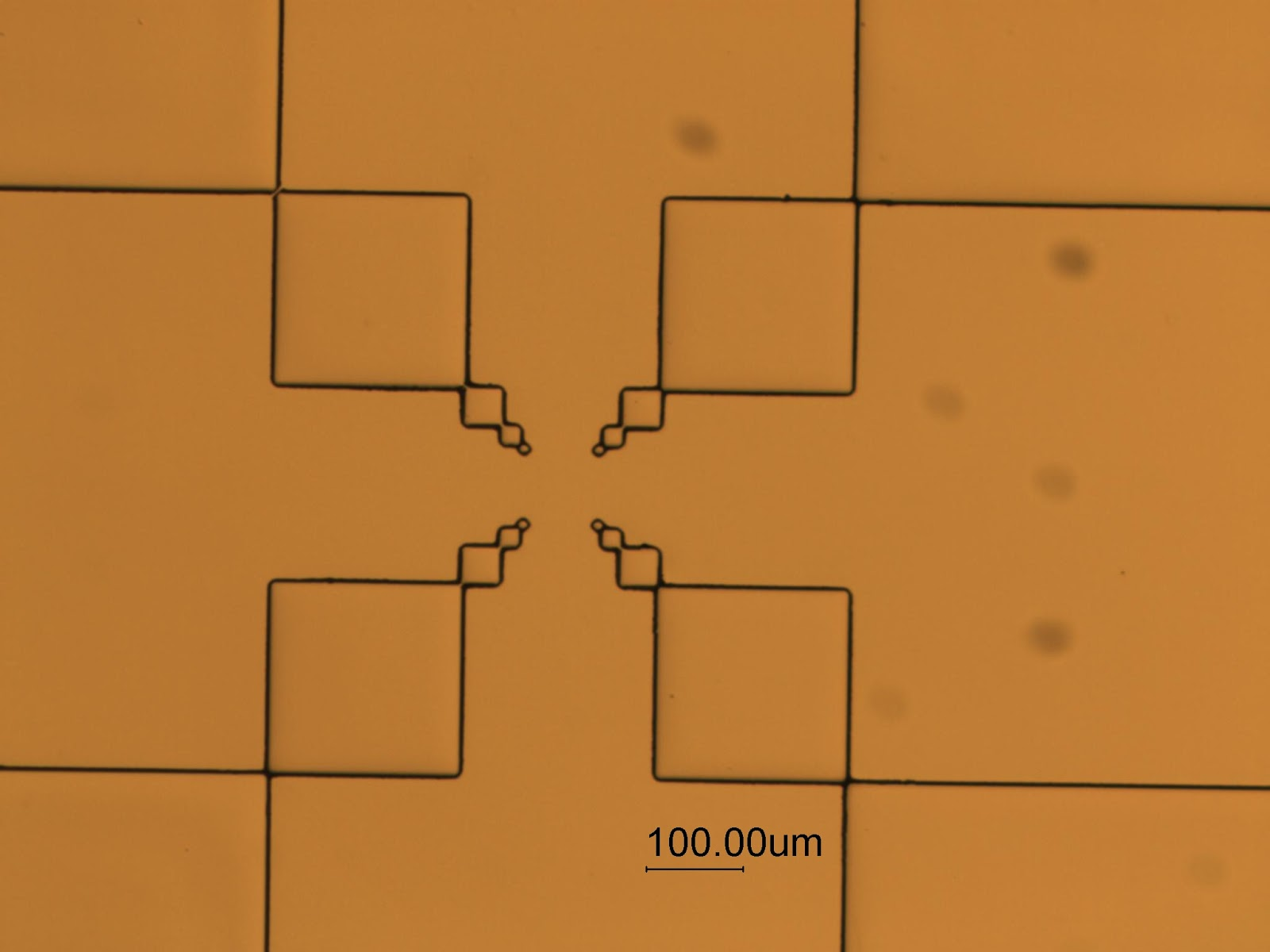

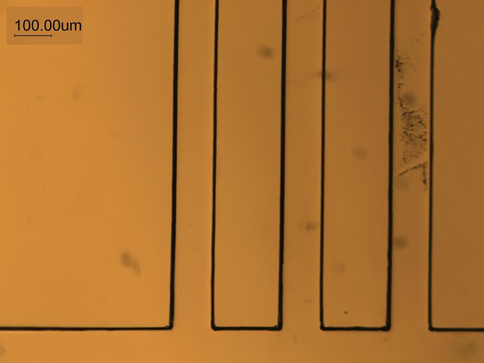

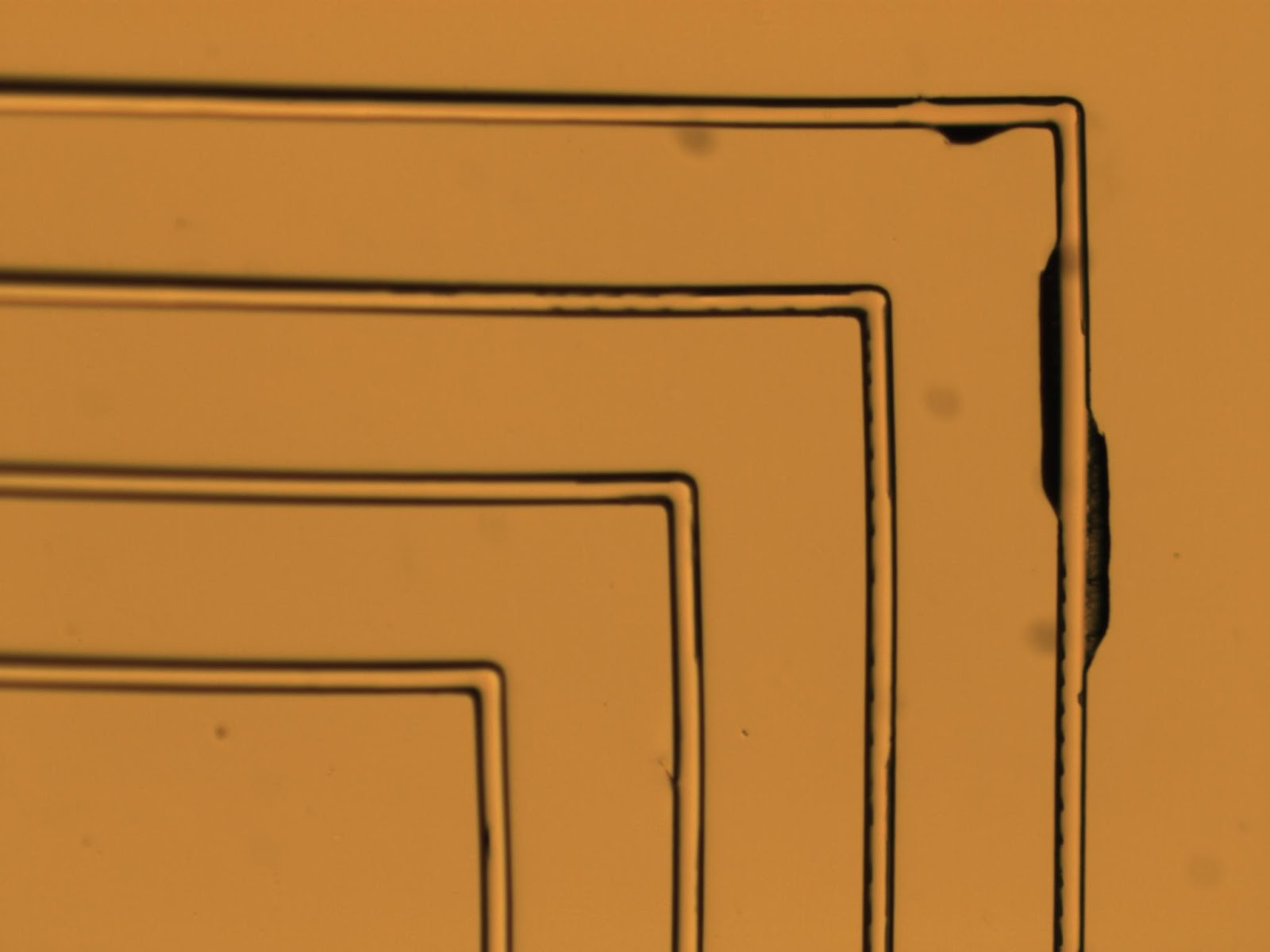

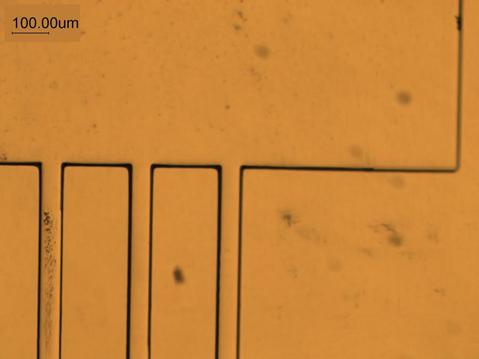

PDMS Microchannel Fabrication

Apr 2017

Overview

Keywords: SU-8 Microchannel Mold, PDMS Elastomer, Elastomer Curing Agent, Cleanroom, Reactive Ion Etcher (RIE), Microtechnology, Nanotechnology, MEMS, NEMS, NUFAB

Procedure

- A 10:1 weight ratio of elastomer to curing agent was mixed (20 grams of elastomer and 2 grams of curing agent)

- The edges of the silicon wafer with the SU-8 pattern were taped to create a mold

- The PDMS is then poured into the mold

- Air bubbles were evacuated in a vacuum chamber for 30 minutes

- Next the mold and PDMS were baked in an oven at 90°C for 20 minutes (approximately position 3 on the oven)

- The PDMS was peeled off from the surface of the coated silicon wafer

Technologies Used

- Reactive Ion Etcher (RIE)

- PDMS Elastomer

- Elastomer Curing Agent

- SU-8 Microchannel Mold

- Optical Microscope

- Vacuum Dessicator

- Hotplate